Rheology

Rheology reals with the deformation of materials and how those materials flow under strain. Many materials change their properties at different levels of strain and or strain rates. This makes rheology the study of stress-strain in materials.

A rheometer is used to study the rheological (flow) properties of a material. It is a precision instrument that can evaluate the properties of a material in a controlled environment. A Rheometer can also be defined as a mechanical spectrometer that subjects a sample to either a dynamic (sinusoidal) or steady (linear) shear strain (deformation) and measures the resultant torque in the sample.

It is a key instrument to provide insight into Viscosity and visco-elastic measurements of chemicals, oils, printing inks, lubricants, shear, and loss modulus measurements of plastics (after initial melting), personal care products (e.g., toothpaste, lotions), food & beverages (e.g., dairy products). Adhesives: Curing behavior etc. In addition, it can also provide key insights into mechano-thermal properties such as glass transition, Tg, melting temperature, and coefficient of thermal expansion (CTE) of plastics.

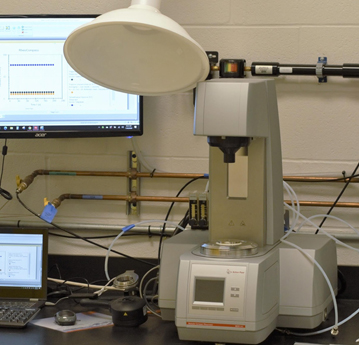

RoCo® is equipped with a state-of-the-art Anton Paar 302 device capable of measuring a variety of liquid/melt properties.

Some Tests which can be Performed Providing Key Insights into your Material Need.

- Viscosity as a function of shear stress

- Viscosity as a function of shear rate

- Viscosity as a function of temperature

- Zero-shear viscosity measurements

- Yield stress and yield strain measurements

- Thixotropic breakdown rate

- Thixotropic recovery rates

- Elasticity under shear measurements

- Structure rigidity, complex, storage and loss modulus

- Phase angle and tan delta

- Oscillatory stress and strain sweeps

- Oscillatory frequency sweeps

- Oscillatory temperature sweeps and cycles

- Creep and recovery

For our customers rheological studies can provide key insights such as:

- Predict suspension or emulsion stability,

- Reformulate with alternative ingredients,

- Benchmark competitors and reverse engineer to a target or reference formulation,

- Understand the impact of processing and filling on the final product,

- Figure out the most viable processing conditions for polymer processing yielding optimal properties.