Climate change is the biggest challenge facing humanity. The global implications are already becoming clear with an increase in wildfires in the Northwest United States, record-breaking heat waves worldwide, and, most recently, the devastating flooding in Pakistan. Drastic changes must be made to mitigate the impact of climate change and eliminate the amount of CO2 emitted into the atmosphere. To do this, an executive order was signed to make the Federal government carbon-neutral and achieve net zero greenhouse gas emissions by 2050 and carbon capture is a must.

RoCo is a vision-driven company focused on developing technologies that can reduce the impact of climate change. We have been at the forefront of developing new materials technologies to capture carbon from the point of source (large scale) and direct air capture. Recently, RoCo spun off Carbon Blade, focusing on CO2 for Direct Air Capture (DAC).

RoCo has developed a highly effective Water-Lean Low Viscosity Solvent to capture CO2 from the large industrial sector. For conventional carbon capture applications, hazardous pollutants are also part of the mix that must be removed. This includes sulfur dioxide (SOx) and nitrogen oxide (NOx), which need to be removed before capturing CO2. The cost of implementing emission control technologies for the removal of SOx and NOx is substantial and can be even more concerning for applications that require high removal efficiency. This leads to a significant impact on the overall economics of the carbon capture processes. One potential solution is demonstrating carbon capture technologies with significant ancillary environmental benefits. If successful, it would result in decreasing the cost of CO2 capture significantly. However, there is little understanding and quantification of the co-benefit pollutant reductions.

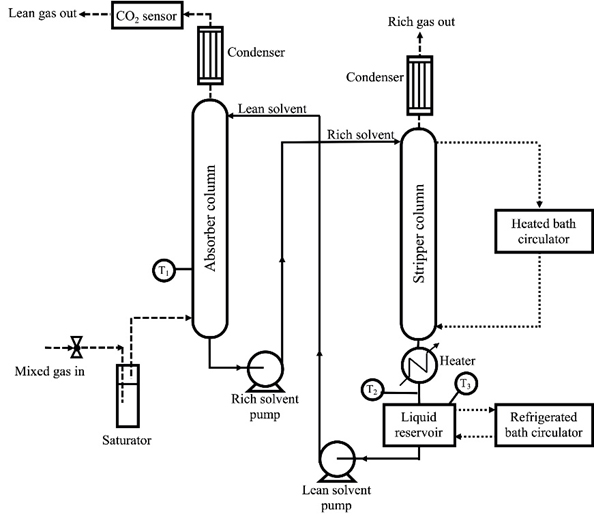

Our newest project is focused on developing technology to further this gap. SBIR-DOE-SC0022623 funds this project. Under this project, the RoCo team aims to understand and quantify the co-benefit pollutant (NOx and SOx) reductions and evaluate their impact on water-lean solvents. The study will provide crucial information for practical process design and more accurate economic analysis that are the foundation for the development, scale-up, and commercialization of RoCo’s solvent technology. RoCo has developed high-performance, water-lean solvents which have a low viscosity. We have identified promising solvent systems with exceptionally low viscosity and two times the working capacity of traditional solvents. RoCo is working on conducting tests at a lab scale under simulated flue gas containing 4% (NGCC) or 15% CO2 (PC), capable of reaching > 95% capture efficiency with SOx and NOx to quantify the auxiliary benefits and reduced the overall cost of capture.

RoCo’s goal is to scale up and implement this technology on a commercial scale for large point source capture sites such as power plants, the metals industry, the cement industry, etc. If successful, this water-lean solvent can further reduce the cost by $5.0/ton of CO2 captured, according to preliminary cost-benefit analysis. The proposed work is essential and would help to determine whether separate emission control units are needed upon implementing the technology, which may lead to an additional cost saving of $600/kW in capital cost and almost $7/kW-year in operating costs.

Partnering with RoCo:

If you are interested in our water-lean solvent technology or our qualification method for carbon removal efficiency, please contact us at info@roco.global for more information.